Dr. Bernd Robertz

Managing Director

+49 174 279 64 65

bernd.robertz_at_smart-coloring.de

Decontamination

All in all, increasing the quality of recyclates will boost market demand and broaden the range of applications. This will be a real turning point for the recyclability of plastics.

Facts and Figures

Global plastics production

- 2020: approx. 370 mio. to, of which in Europe approx. 55 mio. to (15%)

- 2040: doubling of global plastics production to approx. 750 mio. to

Demand Europe

- 2020: approx. 55 mio. to of which approx. 12% HDPE and 19% PP

- Packaging with just under 40% largest share

Recycling potential in the segment Plastic Packaging

Forecasts predict a doubling of global plastic waste from 250 million tonnes to 450 million tonnes between 2018 and 2030. In parallel, the amount of waste sent for mechanical recycling is expected to grow from 12 to 26%, in absolute terms from 30 to 117 million tonnes.

Drivers of demand for high-quality secondary raw materials (recyclates)

- Legislation:

- Introduction of recyclate quotas at EU level

- Introduction of a bonus (-malus) system for recyclability and recycling of packaging

- Release of the use of recyclates also for food packaging (option; release requires defined standards to ensure quality and maintain safety)

- Brands: Voluntary commitments by major brandowners

- Consumer: Sustainability as a trend of the times

Current market situation of recyclates

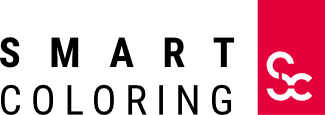

The quality of recyclates is mainly affected by odor, impurities (NIAS) and color.

Low-quality recyclates can therefore only be used for lower-quality products (down cycling) and are thus not available for a genuine recycling loop.

Chemical recycling will make a higher contribution in the long term, but at a very low level (approx. 10% by 2040). In the medium to long term, chemical recycling will not be a solution to the increasing demand for high-quality recyclates, as it is hardly economically viable.

Outlook

(Optimized) mechanical recycling will continue to make a decisive contribution to increasing the quantity and quality of available recyclates for the foreseeable future.

For high-quality reuse, pure, odorless and colorless recyclates free of impurities are required.

In order to ideally meet recyclate quotas, recyclates should be available in different grades (food grade, pharma grade, ...).

Résumé

All in all, increasing the quality of recyclates will boost market demand and broaden the range of applications!

Insights into Smart Coloring´s

Decontamination

Modified mechanical Recycling

Decontamination by solid-liquid extraction simultaneously eliminates unpleasant odors and removes NIAS from the plastic, so that all 3 major challenges for the use of recyclates are addressed at the same time.

It is worth the effort

The additional revenues for high-quality recyclates are higher than the costs for the extended recycling process. Turnover, profit and market share can be increased. The ecological gain is obvious.

The largest proportion of polyolefin waste is colored. So, what good is the most pleasant-smelling recycled material if it is still grey, brown or black at the end?

Modified Mechanical Recycling

- detergents & wetting agents @ pH ≥ 7

- solvent in water emulsion

- reduction agent

- T = 90 – 120°C

- t = 10 – 60min (powder < flake < pellet < object)

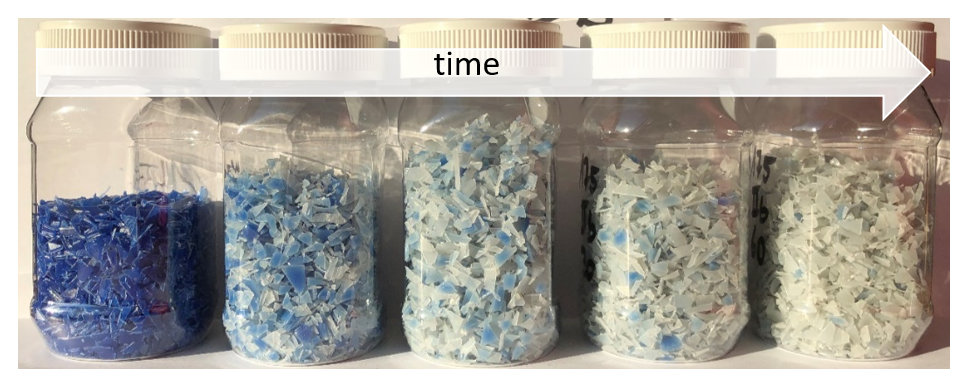

Decoloring of colored shreddered PP-caps:

The decolorization result mainly depends on the temperature, residence time and flake size. For decoloring/decontamination powders would be the best choice.

Residual colorant contents achieved are clearly below 5%.