Dr. Bernd Robertz

Managing Director

+49 174 279 64 65

bernd.robertz_at_smart-coloring.de

LASER DEEP PRINTING

An effective method to introduce light shielding into transparent plastics.

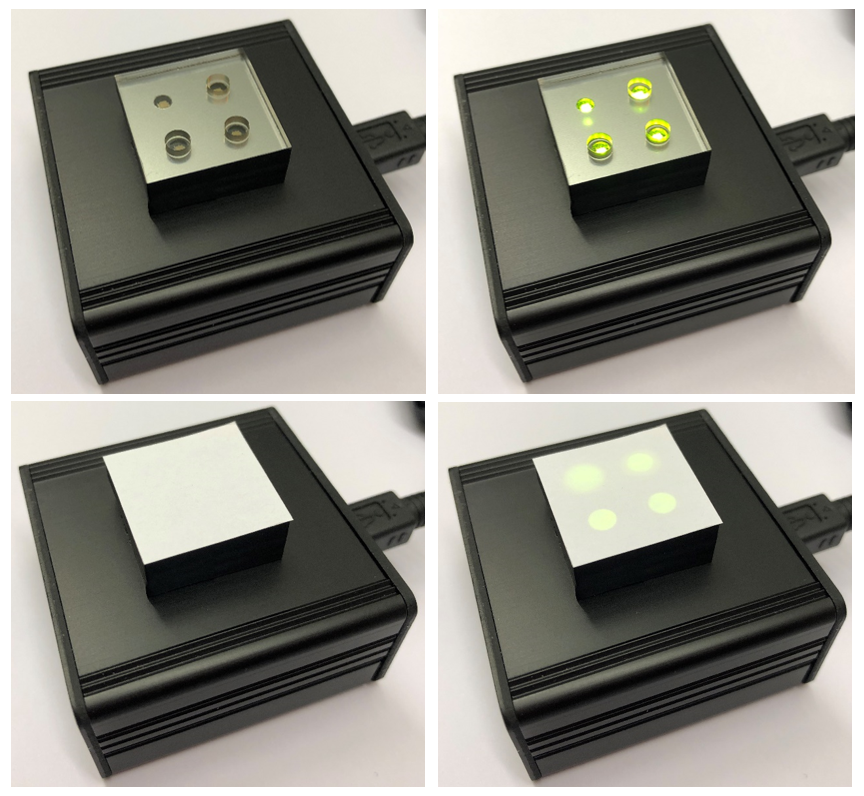

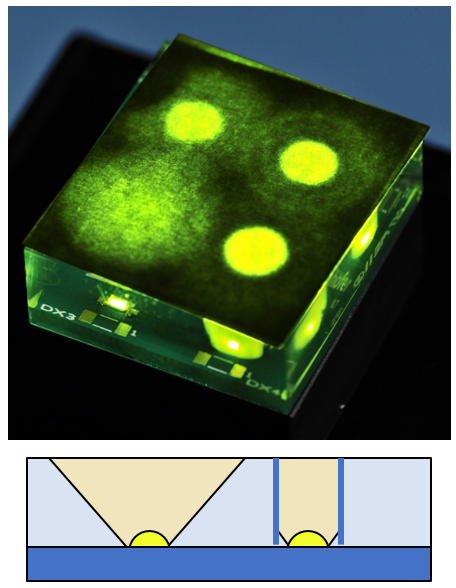

Light shielding in backlit components avoids light bleeding into neighboring operating elements.

- Laser Deep Printing requires no laser-absorbing additives for modification at depths of up to several mm.

- Laser Deep Printing requires no changes in the process flows as it takes place at the very end of the manufacturing process.

- Laser Deep Printing can efficiently introduce homogeneous light shieldings into transparent plastic components at reasonable speed and costs.

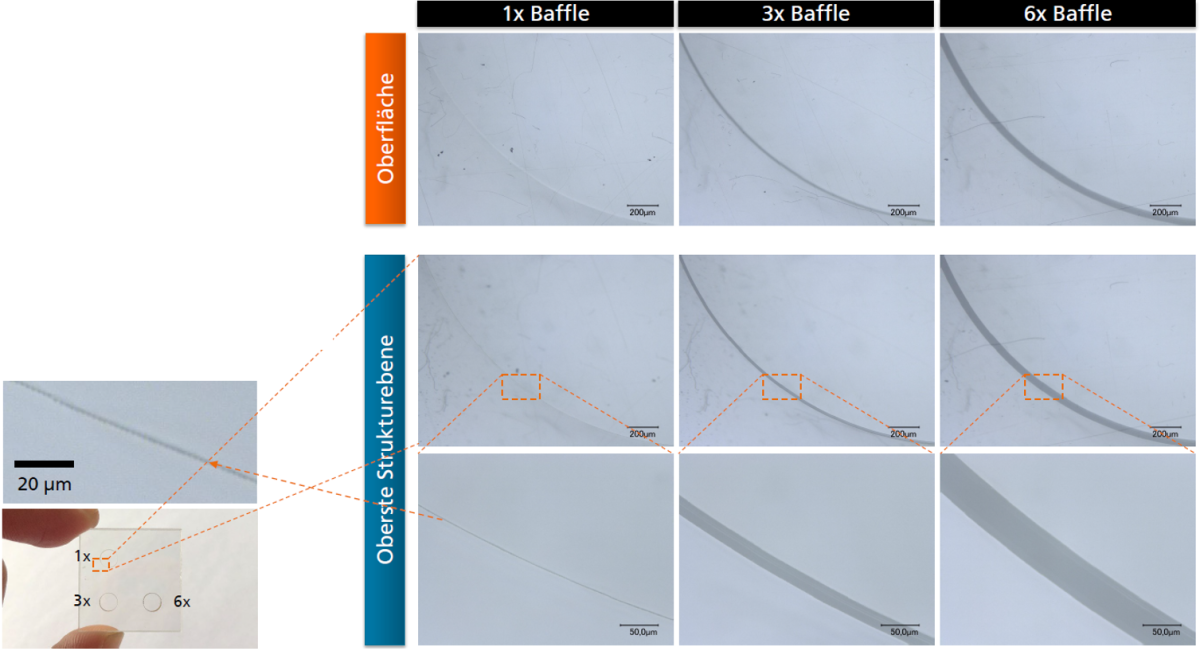

- Light shieldings effectively reduce the transmission to below 35%. Several light shieldings in a row further reduce transmission.

- Plastics: PC, PMMA, PET, ...

Light shielding in backlit components are usually created by elaborate 2-color back injection molding. Laser Deep Printing opens up significant cost savings in terms of

- Investment in machine (1K instead of 2K)

- Energy

- Tool costs

Insights into Smart Coloring´s

Laser Deep Printing

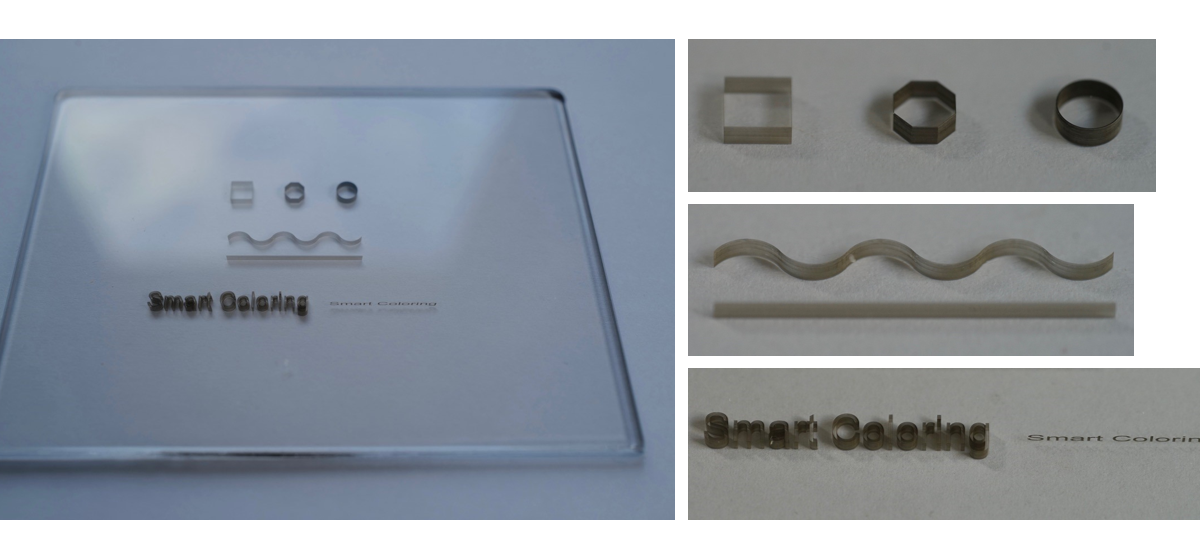

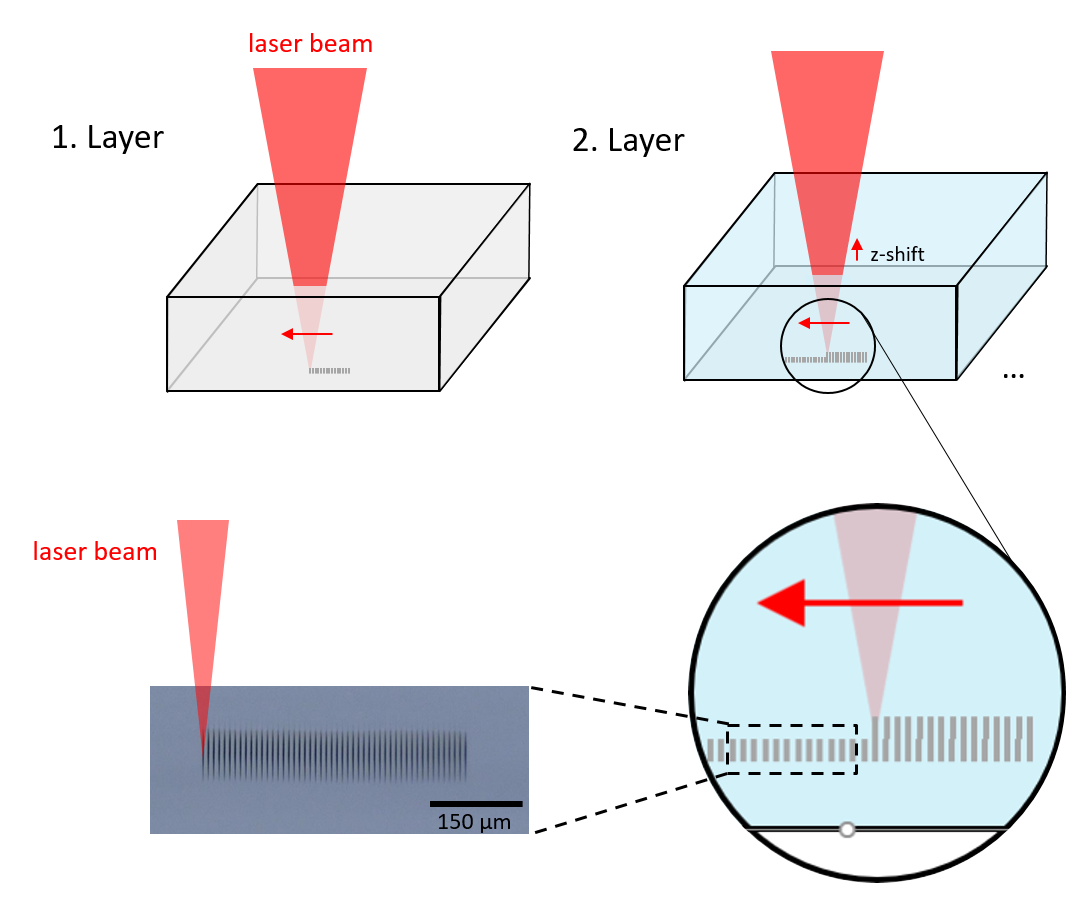

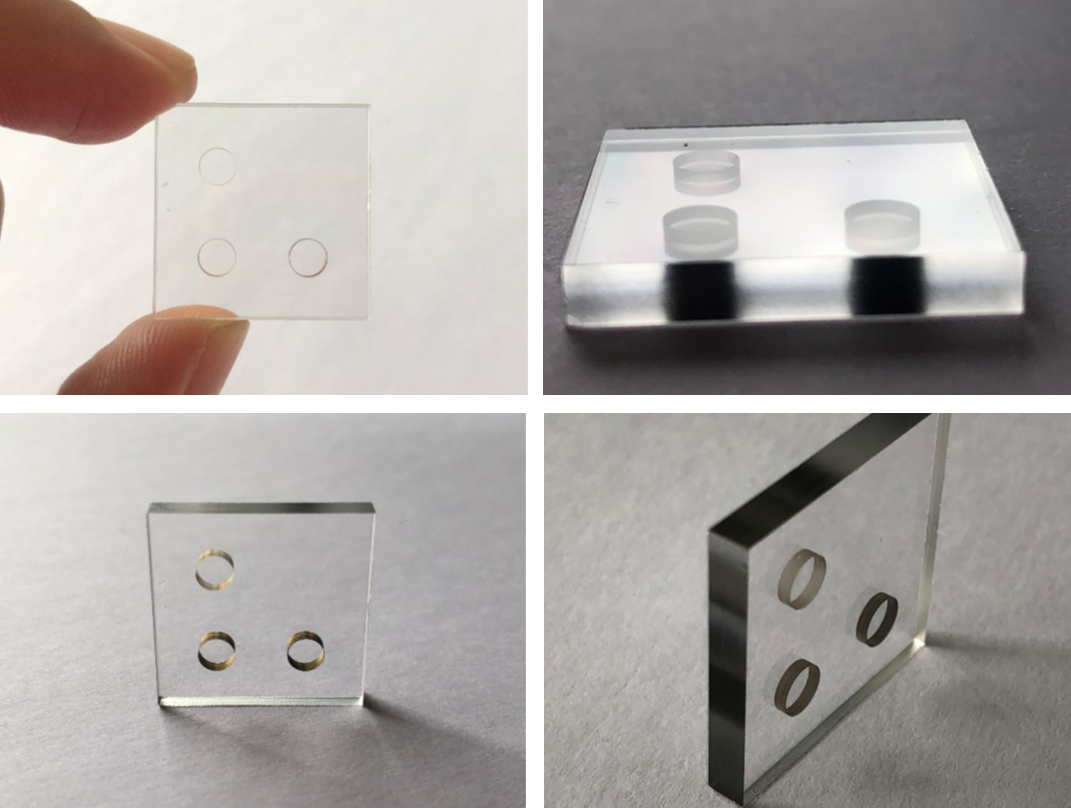

Location-controlled focussing of ultra-short pulsed lasers creates visible dots, lines, areal and even complex geometric structures/shapes in transparent plastics.

Modified structures are built from the bottom up. Single pulse processing leads to separated structural elements.

The effect of spherical abberation leads (without a corresponding corecture) to an expansion of the introduced structure in the z-direction. The expansion in x,y direction remains unchanged.

Minimum structure sizes in x,y, and z-direction are about 2µm.

Laser Deep Printing - Variables

- Puls duration [ps]

- Puls energy [nJ]

- Feed motion [mm/s]

- Puls distance [µm]

- Repetition rate [kHz]

- Depth z [mm]

Cage-like or tubular structures act as a light shielding to prevent over-illumination into neighbouring areas.

The light barriers were introduced into various transparent plastics

- In all plastics, these structures were achieved without the addition of laser-absorbing additives.

- The highest darkening was achieved in PC.

- In PET a medium dark coloration was achieved.

- In PMMA, light/white structures were achieved