Dr. Bernd Robertz

Managing Director

+49 174 279 64 65

bernd.robertz_at_smart-coloring.de

DECOLORING

Fundamentals of Smart Coloring Technology

Of course, only plastics that have been previously colored using Smart Coloring Technology can be decolorized.

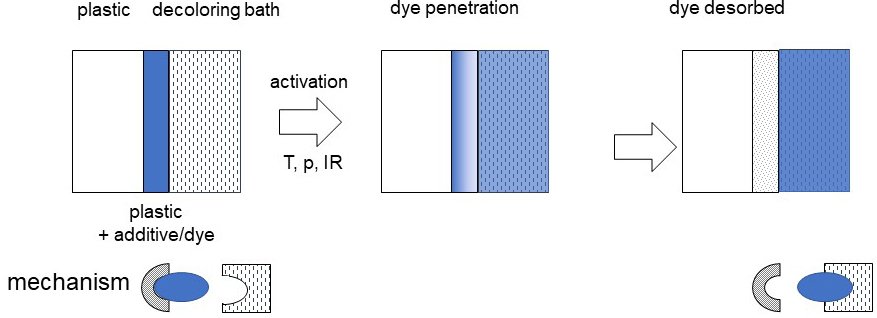

The decolorization, the resolving of the dyestuffs, takes place in an aqueous decolorizing bath at elevated temperature with the addition of dye absorbers. The plastics "open" and release the dyestuffs. These, in turn, are absorbed by the absorbers in the water and removed from the washing water.

Since the additives remain in the plastic, they can be re-colored. Accordingly, it can make sense to decolorize plastic parts as a whole and to dispense with shredding.

The dyestuffs can be removed by means of an aqueous decolorising bath under suitable conditions for reactivating the plastic again.

The contamination of the washing water is avoided by appropriate and easily removable additives to the washing water that absorb the resolved dye.

Unintended migration or color bleeding during application may not occur thru the use of a special key-locker principle.

Decoloring of colored shreddered caps: The decolorization result mainly depends on the temperature and the duration of the decolorization process. Flakes offer a larger surface area and are easier and more efficient to decolorize than components.