Dr. Bernd Robertz

Managing Director

+49 174 279 64 65

bernd.robertz_at_smart-coloring.de

COLORING-On-Demand

Fundamentals of Smart Coloring Technology

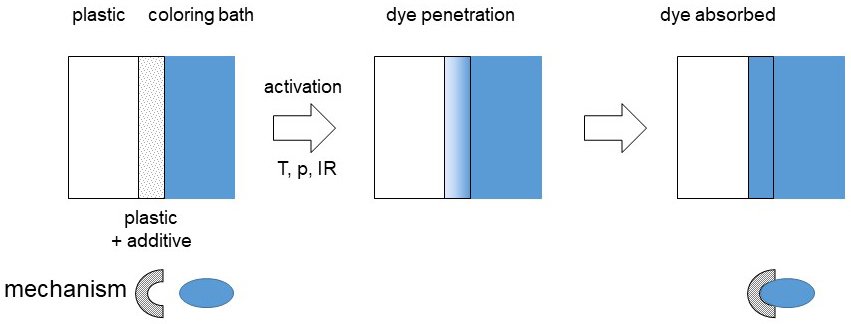

The basic prerequisite for the subsequent coloring of plastic films, parts or general objects is the ability of these plastics to store organic and/or inorganic substances such as dyes in the plastic matrix and to bind them there. In order to make this possible, we add suitable additives to the plastics in combination with selected dyestuffs for coloring. The basis of our technology for the reversible coloring of plastics is therefore a suitable additive-dye combination.

Some plastics can also be dyed with our dyestuffs without the necessity of additivation. Here, however, the dyestuffs are not firmly bound to the plastic matrix, so that uncontrolled migration occurs. This makes its use in applications such as direct food contact impossible.

Our additives prevent this through a key-locker principle. Nevertheless, we strongly recommend to carry out application-specific tests.

By adding additives to the plastics the basic possibility of coloring as such, sufficient storage capacity for dyestuffs and ways of removing the dyestuffs are created. Accordingly, dyeing is only carried out in the areas where the additive has been added, e.g. in the case of multi-layer laminates only in individual layers.

The basic prerequisite for the coloring of plastics is the ability of the plastics to be activated for migration of dyes and to trap these dyes in the plastic matrix – most of all enabled by the addition of suitable additives to the plastic.

Selective coloring e.g. of multilayer plastics is simply realized by selective additivation only of the parts to be colored (see below: body-skin concept)

The addition of additives accelerates the dye migration and ensures efficient processes.

The cross section of the colored plastics shows a sharp phase boundary between the additive and the nonadditive phases.