Dr. Bernd Robertz

Managing Director

+49 174 279 64 65

bernd.robertz_at_smart-coloring.de

Rethink Plastics with Smart Coloring

ONE COMPANY – TWO TECHNOLOGIES

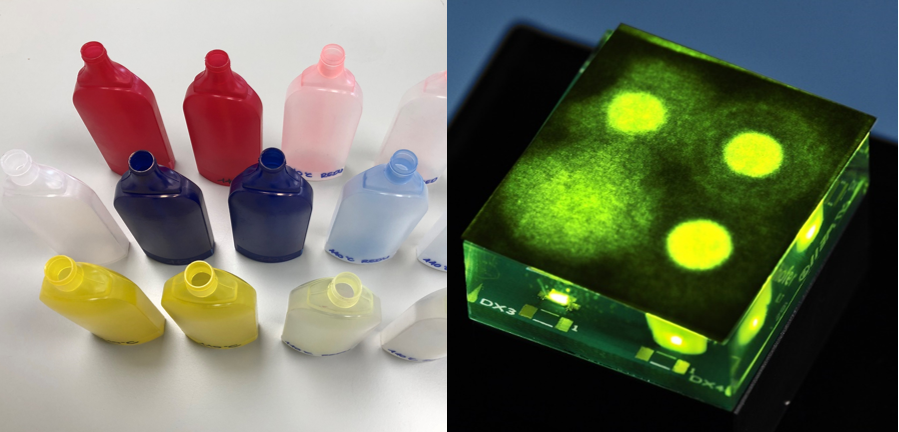

REVERSIBLY COLORING

Decolorisation - Deodorisation - Removal of NIAS

all at the same time - in one process - in one step

LASER DEEP PRINTING

Laser based introduction of light shielding into transparent pastics.

REVERSIBLY COLORING

Reversibly Coloring is a combination of coloring and decoloring of plastics (ColorIn & ColorOut). Our focus is on polyolefins, but reversible coloring is possible with a wide range of plastics.

Masterbatches can be used within established infrastructure on the existing converting machines. Coloring-on-Demand allows the production of smaller lot sizes at reasonable costs.

Decoloring is an essential part of decontamination to improve the availability and quality of recyclates.

ColorIn & ColorOut

Coloring-on-Demand A selected combination of additives and dyes enables the subsequent and reversibly coloring of various plastics.

Coloring-by-Masterbatches Reversibly coloring using pigments or dyes within established infrastructure on the existing converting lines

Decontamination : In a modified mechanical recycling process, colors, odoros substances and impurities (NIAS) are effectively removed simultaneously by means of solid-liquid extraction.

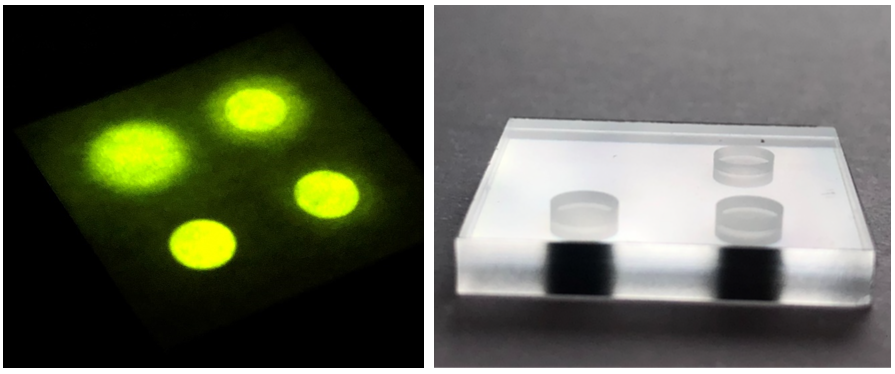

LASER DEEP PRINTING

Laser based introduction of light shielding into transparent plastics

Location-controlled focussing of ultra-short pulsed lasers creates visible dots, lines, areal and even complex geometric shapes in transparent plastics. Cage-like or tubular structures act as a light shielding to prevent over-illumination into neighbouring areas.

Laser Deep Printing succeeds without laser absorbing additives and without changing standard processes such as FIM or IMD

CONNECT

We are a young company but with many years of wide-ranging experience in the production and processing of plastics:

film extrusion, injection molding, film insert molding, blow molding and thermoforming, coating, analogue and digital printing, ink development and much more.